| Loading Capacity | 100-3500t/h |

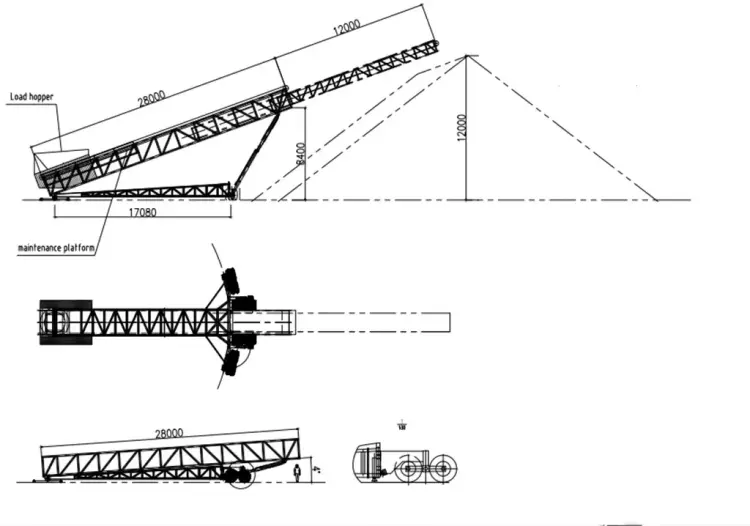

| Conveyor Length | 25m-65m (65.6ft~213.25ft), Fully Extended Length |

| Loading Height | 9.3m-22m (30.5ft~72.2ft), Max. Height |

| Driving Modes | Fuel Diesel Driving and Electric Driving;Dust extraction, Integrated telescopic chutes (Free-fall – Cascade Design);360 degree trimmer chutes;Water suppression and many more. |

| Travelling Modes | In-line Travel;Carousel Mode;Radial Mode;Parallel Travel;Crab Mode |

| Electrical Integration | Communication interlinks, Radio remote controls,Fully integrated generators, Ethernet connections and many more. |

If you have any queries, get in touch today! Don't hesitate. We try to take the extra step for our customer satisfaction.

As core equipment for mining, port, and construction industries, Zoomry's conveyor telescopic achieves engineering limits through modular design and intelligent control technology, delivering 20-meter stacking precision and 85-ton/hour processing capacity to redefine bulk material handling standards.

| Industry Scenario | Pain Points | Zoomry Conveyor Telescopic | Customer Value |

|---|---|---|---|

| Mining & Quarrying | Open-air material weathering/pollution | Fully enclosed belt system with 75° climbing capacity (-30°C to 50°C adaptability) | Ore moisture control <3% (ISO 13315) |

| Port Operations | Vessel demurrage costs >$15,000/hour | Rapid mode switching (15-minute barge-truck conversion) | Loading efficiency ↑40% |

| Construction Waste | 50MPa concrete debris equipment damage | Manganese steel scraper + dual-chain drive (>8kN/m² impact resistance) | Equipment lifespan extended to 10 years (Industry average: 6 years) |

| Grain Storage | >2% grain breakage losses | Low-speed gentle conveying (0.5m/s) + FDA-compliant TPU belt | Breakage rate reduced to 0.3% |

| Chemical Materials | Corrosive material structural damage | 316L stainless steel frame + EPDM sealing (pH 1~14 resistance) | Maintenance cost reduction $0.8/ton |

The conveyor telescopic comprises:

Ensuring holistic performance and reliability.

Fast, professional and reliablewe provide you with servicesthroughout the productlifecycle.

CONTACT USDaJin Cheng Building, Tian Jin City, China.

oversea@zoomry.cn

+86-13164016717

product

part

quick access

Zoomry Group Company Limited